Since its inception in 2012, the SSI™ dental implant system has established itself as a reliable solution for immediate implantation and loading. Engineered with self-drilling capabilities and a unique spiral body design, it supports precise placement and ensures robust primary stability even in the most challenging clinical scenarios. The system demonstrates versatility across a wide range of applications, proving especially effective in 'All-on-four' and 'All-on-six' procedures. Prioritizing stability and longevity, it accommodates both immediate and delayed loading scenarios. Globally adopted by dental professionals, the consistent performance of SSI™ underlines our commitment to quality. Further, the system encompasses a range of features that optimize implantation and outcomes. These include a precise internal hex system, a single prosthetic platform that fits all diameters, and a design that prioritizes the protection of anatomical structures.

Select Sizes93 items

29 items

2 items

48 items

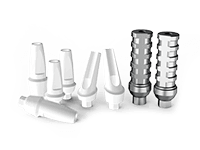

Precision-engineered components that simplify and enhance traditional impression-taking protocols.

Crafted for precision casting, ensuring perfect fits and streamlined procedures for every case.

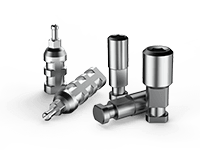

Titanium abutments, both straight and angulated, tailored for reliable cement-retained solutions

Essential for post-implantation, facilitating tissue healing and guiding gum formation

Offering both PEEK and Titanium temporary abutments for interim phases ensuring durability and aesthetics.

A range of units to support complex restoration tasks, ensuring consistent outcomes and patient satisfaction.

Comprehensive solutions for overdenture cases, guaranteeing patient comfort and function.

Ti-base, scan body, and digital analog solutions with full Exocad library support for seamless digital workflows.

SIMPLICITY IN VERSATILITY

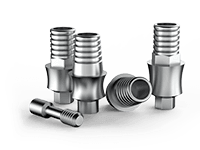

Perfecting the art of platform switching, we reduce crestal bone loss. Our design shifts the inflammatory zone away, enhancing implant stability and aesthetics.

Our one-size-connects-all design streamlines dental implantology. With a single platform for all diameters, we minimize inventory complexity and maximize clinical convenience.

Striving for a near-zero micro gap, our precision manufacturing process minimizes bacterial infiltration and micro-movement. This commitment to quality assures a robust, stable connection.

Our design considers natural biology, promoting healthy gingival growth around the implant. This commitment enhances aesthetics, patient comfort, and overall satisfaction.

Experience the confidence that comes from using our globally trusted SSI™ dental implants, chosen by dental professionals worldwide.

Packaging

Our dental implant packaging system is designed to offer safe and convenient experience for dental professionals. It features double tube sterile packaging, sealed blister, outer carton box, carrier for easy handling and a cover screw for smooth implantation.

Evidencing excellence in clinical practice is at the heart of what we do. This video presentation offers a unique opportunity to observe our dental implants in their operational environment, demonstrating their quality, reliability, and superior functionality. Each implant reflects our commitment to industry-leading design and innovative technology, enabling optimal patient outcomes and practitioner ease-of-use. Experience the true measure of our product performance as you view our dental implants at work. The difference is discernible - because the proof, indeed, is in the performance.

Chinese American Dental Society Of Southern California

Chinese American Dental Society Of Southern California

American Dental Association

American Dental Association

Superior Potency Revolutionary Courses

Superior Potency Revolutionary Courses

Medical Device Manufacturing Certificate

Medical Device Manufacturing Certificate

FDA510(k) Approval For Certain Implant Products

FDA510(k) Approval For Certain Implant Products